THE NATIONAL PLAN FOR RESEARCH, DEVELOPMENT AND INNOVATION 2007-2013

- PROGRAMME 5 - INNOVATION

Management Agency for Scientific Research, Innovation and Technological Transfer

- University POLITEHNICA of Bucharest -

INFOLAM Project

- Information and automation system for management and control of production process of cold rolled steel strips -

Presentation :: Stage I :: Stage II :: Stage III :: Stage IV :: Stage V

Quick navigation:

GENERAL PRESENTATION

ABOUT THE PROJECT

PARTNERS

GENERAL PRESENTATION

ASPECTE INOVATIVE

1. Characteristics:

The thin cold rolled steel strips are part of metallurgical products category with a high added value. The project main aim consists in raising the competitiveness level of SME's in the mentioned activity field, by capitalizing on the results of technological knowledge and innovation. Under the conditions of strong foreign competition, preserving the jobs in this activity field involves urgent modernization and technology renewal. Production of superior quality steel strips, in point of metallurgical structure and geometric parameters of thickness and flatness require existence of a high-performance process and management information system combined with latest generation measurement, execution and automation elements.

A few technical characteristics of the new technologic achievements used within this project are presented bellow:

· Adjustment accuracy of speed, torque and position of rolls is of the order of 0.01% as opposed to 1-2% in case of existing equipment;

· The strip thickness tolerance will be +/-1Ám as opposed to +/-10Ám which is currently achieved. For thickness of 0.07 mm strips, a tolerance of +/-0.5Ám will be achieved while rolling at a speed of 300m/min;

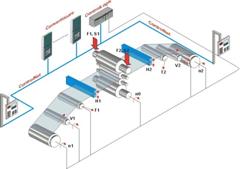

The technology used to achieve project objectives is structured and will be implemented in point of hardware and software, on three levels:

Level 1, corresponding to process equipment (computers, transducers , execution elements), the basic function being achieved by the Automatic Gauge Control (AGC) system for strip thickness and flatness adjustment. The AGC system involves real-time algorithms and signal processors with high computing power. The financial effort required for implementing of AGC system amplifies due to required performances of transducers used. These are transducers for measurement of strip thickness, rolling forces, strip tension and speed. The costs of these transducers are higher as the specified thickness tolerances are lower.

Level 2 achieves the functions of elaboration, control and analysis of production schedule with the purpose of optimizing them by off-line models.

Level 3 corresponds to global management and optimization of production process (integration with ERP-type software packages).

All these control levels are connected both horizontally and vertically to the company industrial communication backbone.

2. Novelty degree

Recent strategies are used within this project for control of industrial processes, among which: real-time models with variable (adaptive) structure for optimal control of rolling process; on-line status identification of execution elements for sensing and correcting of functional characteristics modifications; advanced statistical analysis of strip geometrical and structural performances; modern solutions of hardware and software implementation using modern work stations, latest generation PLCs, real-time control systems, industrial communication networks organized on three levels.

The technical solutions adopted in the project have an advanced degree of novelty considering that they resulted both from capitalizing on previous research, as well as by competences acquired by the automation team of Galfinband S.A. confirmed by reference projects completed in the metallurgical industry. The novelty also reflects in the patents which will result after capitalizing on some “ soft-sensor ” solutions. These solutions result in important economy by replacing some purchases of expensive transducers with new, alternative solutions (algorithms and methods implemented by software means).

3. Competitiveness level

An important objective of the project consists in achieving a new technology based on the automatic thickness and flatness adjustment system for rolled products (AGC). Please note that, this type of modernization with foreign licenses, have not been implemented in our country before due to the very high costs. Worldwide, there are a few research teams and universities which work on control of cold rolled strips fabrication processes. Most of technologies existing in Romania have been implemented through foreign companies. The field of cold rolling of steel strips is rather unexplored in our country, concerning gathering it into a coherent and realistic model which will assure achieving European level performances. The main cold rolled steel mills in Romania are presently at the same level of commissioning year, at the best, of insurmountable physical and moral wear have occurred.

Generally, these cold rolled steel mills, achieve the final strip thickness by mostly manual processes, with a very low degree of parameter anticipation and pre-adjustment. As a result, only 20% of domestic production is at the level of European performances (where the mills have been brought up to date), with corresponding technical and economic effects. These gaps increase as, worldwide, the specified thickness tolerance is under 2% of nominal thickness or even under 1% for 98% of a coil length.

We estimate that the performances of solutions recommended in this project are at European level, at least. We base on the numerical simulation works already performed and on the prestige of Rockwell Automation company which will be the supplier of hardware equipment used in the project.

ECONOMIC EFFECTS

1. Effects at the producer

Average costs from production of the automation system: lei 1.470.000 / pc., of which the material costs represent approx. 50%. At an estimated production of 2 pcs./year, it is estimated that the producer (Galfinband SA) will obtain a benefit of approx. Lei 1.470.000 in the first 5 years. Production of automation systems will have positive effects upon the state budget by increasing the incomes due to increase of collected taxes (VAT, profit tax, employees' contributions, taxes withholding). We estimate that in the first 5 years, these income increase at the state budget will amount lei 2.174.850, of which VAT 1.396.500, profit tax – lei 235.200, contributions afferent to wages paid by the employer – lei 250.650, contributions and taxes paid by employees – lei 292.500.

Galfinband SA, through its production unit, capitalizes on the results of this project immediately, by implementing the pilot installation. The economic benefits resulted from the activity of producing cold rolled steel strips are: Production increase with approx. 50%, positive effects upon the state budget by increasing the income due to increase in collected taxes. We estimate that in the first 5 years, these income increases at the state budget will amount lei 2.303.635, of which VAT lei 994.750, profit tax - lei 279.230, company contributions lei 488.650, contributions and taxes paid by the employees – lei 541.005. Other benefits: creation of 4 new jobs in the Research, Development and Innovation Department.

2. Effects at the user

The business plan was elaborated based on the estimation of benefits resulted by implementing the solution proposed by project and of required expenses. The information in the bulletins provided by the Romanian Center for Promotion of Commerce confirm the fact that there is an actual demand uncovered on the market for cold rolled steel strips, in 2008 the quantity imported exceeding the exported quantity significantly. The benefits resulted from increase of rolled strip quality and superior capitalizing on raw material can be estimated by the model of tradition firms. The users of the new technology and new integrated automatic tracking and control system achieved by Galfinband SA are companies which process steel or non-ferrous strips, which have their own rolling mills quarto-reversible type, tandem type or Senzimir type.

By implementing the results of this project the following performances will be obtained: Achieving a profit dynamics of min. 10% each year; Increase in the turnover to approx. 10% / year; Savings for the budget of beneficiary company by decreasing the maintenance and operation staff number as well as increasing the equipment lifetime; Decreasing of consumption and expenses per tone of rolled product; Increasing rolling mill operation safety and constancy and prevention of accidental pollution.

>> Back to contents

ABOUT THE PROJECT

Project title:

Information and automation system for management and control of production process of cold rolled steel strips

Acronym:

INFOLAM

Project number:

INNOVATION - 1310

Contract number:

INNOVATION - 237/08.10.2008

Project tacks place:

Within the Innovation Programme – Module 1 – Product development – systems, from the National Plan for Research, Development and Innovation II, approved by Romanian Government at the initiative of Ministry of Education, Research and Youth. The general aim of the INNOVATION Programme is to increase the innovation, technological development capacity and assimilation of research results into production, with the purpose of improvement of national economy competitiveness and increase of life quality.

Research project INFOLAM falling into:

Project category:

PDT – innovation and technological transfer projects for technology development

Project type:

CDI - oriented

Data regarding the Research project

Date of project start:

October 8, 2008

Date of project completion:

September 30 2010

Project development period:

24 months

Contracting authority:

MANAGEMENT AUTHORITY FOR SCIENTIFIC RESEARCH, INNOVATION AND TECHNOLOGICAL TRANSFER - POLITEHNICA

>> Back to contents

PARTNERS

The "Low Danube University" of Galati - Project responsible person: Prof. Dr. Eng. Sergiu Caraman

Domneasca Str. no. 111

Post code: 800201

Tel./Fax: +4-0236-460182

Web-site:

www.ugal.ro

>> Back to contents